|

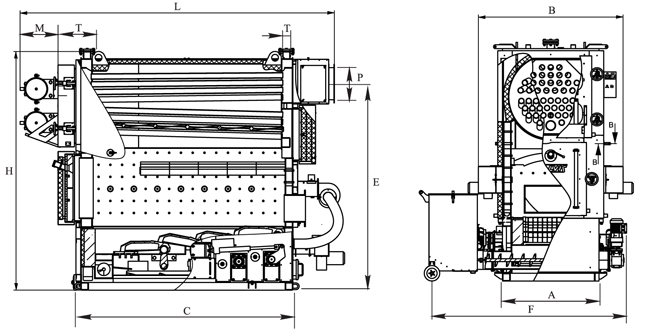

Boiler type |

K-140M1 |

K-320M1 |

K-500M1 |

K-720M1 |

K-950M1 |

|

H, mm |

2105 |

2480 |

2610 |

2765 |

2950 |

|

B, mm |

1300 |

1500 |

1630 |

1630 |

1840 |

|

L, mm |

1900 |

2810 |

2840 |

3640 |

4180 |

|

A, mm |

800 |

1000 |

1400 |

1400 |

1400 |

|

C, mm |

1400 |

2160 |

2620 |

2920 |

3220 |

|

D, mm |

486 |

746 |

846 |

900 |

900 |

|

E, mm |

1534 |

2154 |

2370 |

2520 |

2520 |

|

F, mm |

1500 |

1970 |

2400 |

2400 |

2400 |

|

M, mm |

304 |

374 |

400 |

400 |

400 |

|

P, mm |

Ø240 |

Ø325 |

Ø380 |

Ø380 |

Ø480 |

|

T, mm |

Ø76 |

Ø76 |

Ø89 |

Ø89 |

Ø89 |

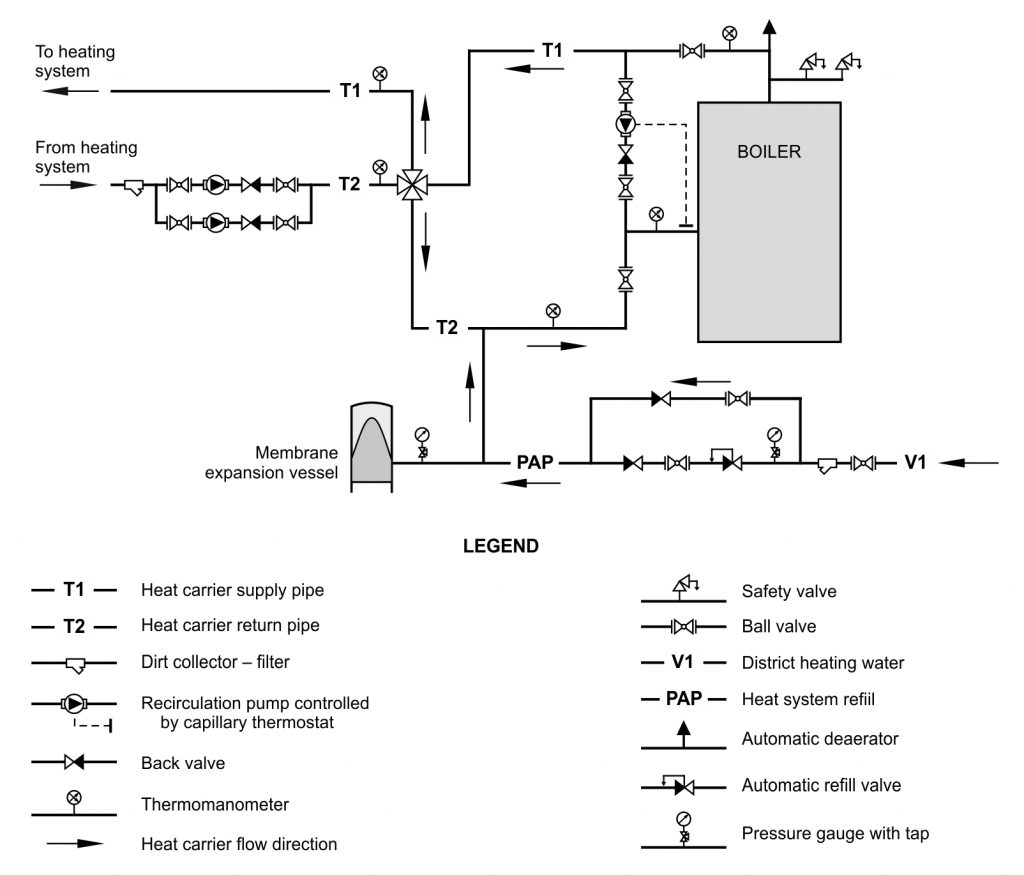

Recommended connection to the heating system diagram: